- sales@aumax-plast.com

- 008613819843291

The industrial water chiller is a energy-saving machine that reaches the cooling effect by steam compression or absorption cycle. Billion times chiller is called the cooling water circulation machine, also called refrigerator, cooling machine, freezer, water water unit, ice water machine, small water purifier, industrial chiller, refrigeration unit, low temperature water machine, laser chiller, because each industry Widely used, so, according to the industry, the alias is not counting, our company mainly produces air-cooled chiller, water-cooled chiller, screw chiller and filling line industrial chiller.

1. Principle of industrial chillers: The refrigerant-through compressor is converted into a cold amount, and the heat generated when the machine is operated by the cold water.

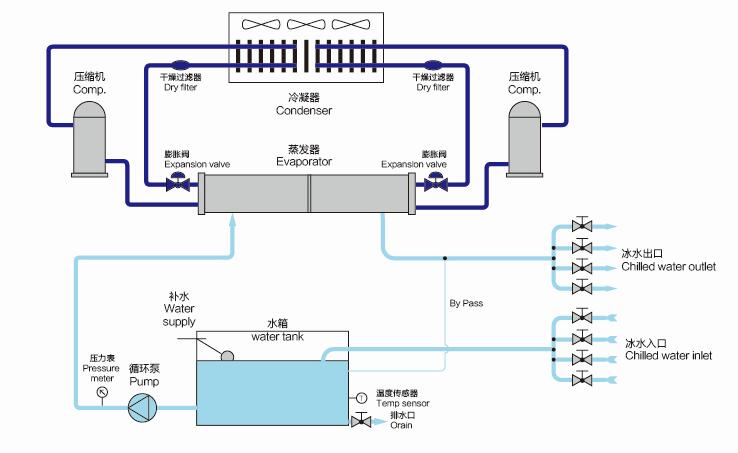

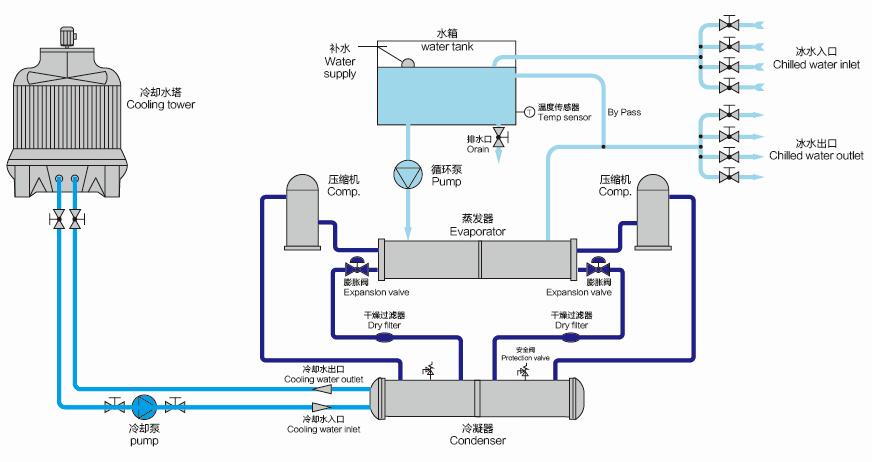

2. Working principle

Water cooled principle diagram

3. Industrial chiller unit characteristics

a. High quality compressors as the heart of industrial chiller (using Japan new original compressor, built-in security, low noise, power saving).

b. the water tank type evaporator built-in automatic hydrating device, saving the Pengzi water tank in the project installation and convenient installation and maintenance, suitable for special occasions such as large temperature differences.

c. Water-cooled condenser uses the latest high-efficiency external threaded copper tube, the amount of heat dissipation is large, and the size is small. Using the latest CADCAM processing technology, cooperate with CNC machining center, compact structure, high reliability, beautiful appearance, and efficient energy saving.

d. Industrial chiller unit configuration: Configure a single-chip control system, the built-in compressor drying filter over and the expansion valve, the maintenance valve interface, etc., ensures that the machine is reliable and safe to operate, which is convenient for maintenance and maintenance.

e. industrial chiller microcomputer control panel, compressor switch button, pump switch button, electronic temperature controller, various safety insurance fault lights, unit start operation indicator, simple operation, easy to use.

f. Industrial chiller unit configuration: Configure a single-chip control system, a built-in compressor drying over and an expansion valve and other devices, ensuring that the machine is reliable and safe to operate, which is convenient for maintenance and maintenance.

4. Water machine applications: the chiller is mainly used in plastic industries: plastic molding , Injection molding, extrusion, blowing, thermal plastic, mechanical industry: laser technology, welding, mechanical cutting, non-cutting processing, casting, electroplating, electronics industry: surface treatment, electroplating, electrophoresis, medical equipment, electronics industry, circuit Board production, electronic core manufacturing, chemical industry and other industries: chemical, paper, pharmaceutical industry, food processing industry, aluminum profile, aluminum alloy, tempered glass, coated glass production, ultrasonic cleaning, jewelry processing, leather, fur processing, Ink production, aquaculture industry.