- sales@aumax-plast.com

- 008613819843291

Screw Type Compressor Water-cooled Chiller

AMC-40WS AMC-50WS AMC-60WS AMC-70WS AMC-80WS AMC-90WS AMC-110WS AMC-120WS AMC-150WS AMC-180WS AMC-200WS AMC-40WS-D AMC-50WS-D AMC-60WS-D AMC-70WS-D AMC-80WS-D AMC-90WS-D AMC-110WS-D AMC-120WS-D AMC-150WS-D AMC-180WS-D AMC-200WS-D

Product details

Specification:Single compressor specifications:

| Name | Screw Compressor Type Water Chiller Machine | |||||||

| Model | AMC-40WS | AMC-50WS | RCMC-60W | AMC-70WS | AMC-80WS | AMC-90WS | ||

| Power resource | - | 3Ø-380V-50HZ | ||||||

| Chilling capacity | kcal/h | 113500 | 141900 | 166000 | 191800 | 220200 | 272600 | |

| kw | 132 | 165 | 193 | 223 | 256 | 317 | ||

| Consumption | kw | 31 | 38 | 43 | 51 | 58 | 76 | |

| Operation current | A | 54 | 66 | 75 | 87 | 96 | 123 | |

| Startup current | A | 218D/411D D | 269D/508D D | 290D/485D D | 350D/585D D | 350D/585D D | 520D//801D D | |

| Capacity control | % | 100-75-50-25-0 | ||||||

| Compressor | Type | - | Half-closed and double-screw type | |||||

| Quantity | - | 1 | ||||||

| Startup type | - | Divided winding starting | ||||||

| Oil heater | W | 200 | 300 | |||||

| Chilled oil | Type | - | B320SH | |||||

| Filling quantity | L | 9 | 15 | 22 | ||||

| Refrigerant | Type | - | R-22 | |||||

| Filling quantity | KG | 21 | 26 | 30 | 35 | 40 | 50 | |

| Throttling | - | Thermostatic expansion valve | ||||||

| Evaporator | Type | - | Tube-in-shell high efficient heat exchanger | |||||

| Chiller water flow | m³/h | 23 | 28 | 33 | 38 | 44 | 55 | |

| Pressure expense | KPa | 54 | 54 | 54 | 57 | 57 | 57 | |

| Water pipe joint | PT | 3" | 3" | 3" | 4" | 4" | 4" | |

| Condenser | Type | - | Tube-in-shell high efficient heat exchanger | |||||

| Chilling water flow | m³/h | 30 | 37 | 43 | 50 | 57 | 71 | |

| Pressure expense | KPa | 54 | 54 | 57 | 57 | 59 | 59 | |

| Water pipe joint | PT | 2-1/2" | 3" | 3" | 3" | 3" | 4" | |

| Protection device | - | High pressure switch, low pressure switch, Anti-freezing switch, fusible plug, compressor over-heat protection, motor over-heat protection, exhaust air over-heat protection, pump over-load protection, oil over-heat protection, phase reverse protection, voltage insecure, cooling water over-heat protection, chilled water flow protection, cooling water flow shortage protection, cooling tower over current protection, and so on. | ||||||

| External dimensions | L | mm | 2175 | 2195 | 2245 | 2860 | 2860 | 2975 |

| W | mm | 935 | 935 | 935 | 1015 | 1015 | 1015 | |

| H | mm | 1430 | 1500 | 1655 | 1710 | 1710 | 1965 | |

| A | mm | 1100 | 1100 | 1100 | 1200 | 1200 | 1300 | |

| B | mm | 690 | 690 | 690 | 790 | 790 | 790 | |

| C | mm | 690 | 760 | 820 | 860 | 860 | 1000 | |

| D | mm | 170 | 190 | 240 | 240 | 240 | 270 | |

| E | mm | 100 | 100 | 120 | 120 | 120 | 160 | |

| F | mm | 75 | 80 | 80 | 125 | 105 | 100 | |

| G | mm | 240 | 240 | 230 | 475 | 475 | 400 | |

| I | mm | 75 | 156 | 170 | 200 | 200 | 315 | |

| Net weight | Kg | 1020 | 1060 | 1270 | 1370 | 1400 | 1870 | |

| Operating weight | Kg | 1120 | 1180 | 1420 | 1550 | 1580 | 2100 | |

| Noise | dB(A) | 74 | 76 | 78 | ||||

| Name | Screw Type Water Cooled Chilling Machine | ||||||

| Model | AMC-110WS | AMC-120WS | AMC-150WS | AMC-180WS | AMC-200WS | ||

| Power resource | - | 3Ø-380V-50HZ | |||||

| Chilling capacity | kcal/h | 312200 | 360300 | 470400 | 541800 | 621800 | |

| kw | 363 | 419 | 547 | 630 | 723 | ||

| Consumption | kw | 80 | 90 | 121 | 136 | 156 | |

| Operation current | A | 136 | 151 | 199 | 221 | 246 | |

| Startup current | A | 612D/943D D | 665D/1023D D | 465Y/1442D | 586Y/1853D | 650Y/2029D | |

| Capacity control | % | 100-75-50-25-0 | |||||

| Compressor | Type | - | Half-closed and double-screw type | ||||

| Quantity | - | 1 | |||||

| Startup type | - | Divided winding starting | Y-Δ | ||||

| Oil heater | W | 300 | |||||

| Chilled oil | Type | - | B320SH | ||||

| Filling quantity | L | 22 | 28 | ||||

| Refrigerant | Type | - | R-22 | ||||

| Filling quantity | KG | 57 | 66 | 86 | 99 | 113 | |

| Throttling | - | Thermostatic expansion valve | |||||

| Evaporator | Type | - | Tube-in-shell high efficient heat exchanger | ||||

| Chiller water flow | m³/h | 62 | 72 | 94 | 109 | 125 | |

| Pressure expense | KPa | 59 | 59 | 62 | 62 | 67 | |

| Waterpipe joint | PT | 4" | 4" | 5" | 6" | 6" | |

| Condenser | Type | - | Tube-in-shell high efficient heat exchanger | ||||

| Chilling water flow | m³/h | 81 | 94 | 122 | 141 | 162 | |

| Pressure expense | KPa | 62 | 62 | 65 | 67 | 67 | |

| Water pipe joint | PT | 4" | 4" | 5" | 5" | 5" | |

| Protection device | - | High pressure switch, low pressure switch, Anti-freezing switch, fusible plug, compressor over-heat protection, motor over-heat protection, exhaust air over-heat protection, pump over-load protection, oil over-heat protection, phase reverse protection, voltage insecure, cooling water over-heat protection, chilled water flow protection, cooling water flow shortage protection, cooling tower over current protection, and so on. | |||||

| External dimensions | L | mm | 2985 | 3010 | 3510 | 3590 | 3595 |

| W | mm | 1025 | 1055 | 1105 | 1150 | 1175 | |

| H | mm | 1975 | 1990 | 2140 | 2155 | 2195 | |

| A | mm | 1300 | 1300 | 1600 | 1600 | 1600 | |

| B | mm | 790 | 790 | 9000 | 900 | 980 | |

| C | mm | 1010 | 1010 | 1120 | 1120 | 1160 | |

| D | mm | 270 | 245 | 275 | 240 | 240 | |

| E | mm | 160 | 175 | 175 | 240 | 240 | |

| F | mm | 100 | 100 | 125 | 130 | 175 | |

| G | mm | 405 | 405 | 550 | 540 | 540 | |

| I | mm | 310 | 245 | 250 | 340 | 340 | |

| Net weight | Kg | 1870 | 2070 | 2790 | 2910 | 3240 | |

| Operating weight | Kg | 2220 | 2340 | 3120 | 3240 | 3760 | |

| Noise | dB(A) | 80 | 82 | ||||

Remark:

1) Condition for parameter test: temperature of chilled water: inlet 12°C,outlet 7°C;temperature of chilling water: Inlet 30°C, outlet 35°C.

2) Noise test: 1m away from the due front of the machine, 1.5m high away from the machine(noise: below 30dB)

3) Any special requirements, have to be advised before order.

Please excuse for not note if some specifications of products are changed.

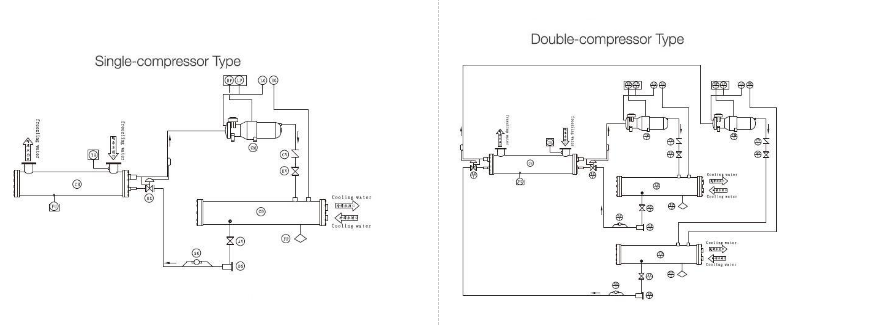

Double compressor specifications:

| Name | Industrial Water Cooling Unit | |||||||

| Model | AMC-40WS-D | AMC-50WS-D | AMC-60WS-D | AMC-70WS-D | AMC-80WS-D | AMC-90WS-D | ||

| Power resource | - | 3Ø-380V-50HZ | ||||||

| Chilling capacity | kcal/h | 226200 | 283800 | 331100 | 383600 | 440300 | 547800 | |

| kw | 263 | 330 | 385 | 446 | 512 | 637 | ||

| Consumption | kw | 62 | 76 | 87 | 102 | 115 | 136 | |

| Operation current | A | 108 | 132 | 149 | 175 | 190 | 232 | |

| Startup current | A | 218D/411D D | 269D/508D D | 290D/485D D | 350D/585D D | 423D/686D D | 520D//801D D | |

| Capacity control | % | 100-75-50-25-0 | ||||||

| Compressor | Type | - | Half-closed and double-screw type | |||||

| Quantity | - | 2 | ||||||

| Startup type | - | Divided winding starting | ||||||

| Oil heater | W | 200x2 | 300x2 | |||||

| Chilled oil | Type | - | B320SH | |||||

| Filling quantity | L | 9x2 | 15x2 | 22x2 | ||||

| Refrigerant | Type | - | R-22 | |||||

| Filling quantity | KG | 21x2 | 26x2 | 30x2 | 35x2 | 39x2 | 46x2 | |

| Throttling | - | Thermostatic expansion valve | ||||||

| Evaporator | Type | - | Tube-in-shell high efficient heat exchanger | |||||

| Chiller water flow | m³/h | 45 | 57 | 66 | 77 | 88 | 110 | |

| Pressure expense | KPa | 57 | 57 | 59 | 62 | 62 | 62 | |

| Water pipe joint | PT | 4" | 4" | 4" | 5" | 5" | 5" | |

| Condenser | Type | - | Tube-in-shell high efficient heat exchanger | |||||

| Chilling water flow | m³/h | 59 | 74 | 86 | 100 | 115 | 142 | |

| Pressure expense | KPa | 51 | 54 | 59 | 59 | 59 | 62 | |

| Water pipe joint | PT | 2-1/2"x2 | 3" | 3"x2 | 3"x2 | 3"x2 | 4"x2 | |

| Protection device | - | High pressure switch, low pressure switch, Anti-freezing switch, fusible plug, compressor over-heat protection, motor over-heat protection, exhaust air over-heat protection, pump over-load protection, oil over-heat protection, phase reverse protection, voltage insecure, cooling water over-heat protection, chilled water flow protection, cooling water flow shortage protection, cooling tower over current protection, and so on. | ||||||

| External dimensions | L | mm | 2850 | 2850 | 3040 | 3130 | 3140 | 3760 |

| W | mm | 1150 | 1150 | 1250 | 1250 | 1250 | 1400 | |

| H | mm | 1450 | 1450 | 1760 | 1790 | 1810 | 2030 | |

| A | mm | 1300 | 1300 | 1300 | 1600 | 1600 | 1600 | |

| B | mm | 1040 | 1040 | 1140 | 1140 | 1140 | 1290 | |

| C | mm | 770 | 770 | 955 | 970 | 975 | 1085 | |

| D | mm | 215 | 215 | 275 | 270 | 270 | 265 | |

| E | mm | 100 | 100 | 120 | 120 | 120 | 175 | |

| F | mm | 230 | 230 | 275 | 300 | 275 | 375 | |

| G | mm | 410 | 410 | 400 | 245 | 400 | 545 | |

| I | mm | 70 | 70 | 245 | 250 | 245 | 250 | |

| Net weight | Kg | 1790 | 1790 | 2340 | 2420 | 2500 | 3580 | |

| Operating weight | Kg | 1920 | 1970 | 2520 | 2620 | 2710 | 3920 | |

| Noise | dB(A) | 72 | 76 | 80 | ||||

| Name | High Capacity Industrial Water Chiller | ||||||

| Model | AMC-110WS-D | AMC-120WS-D | AMC-150WS-D | AMC-180WS-D | AMC-200WS-D | ||

| Power resource | - | 3Ø-380V-50HZ | |||||

| Chilling capacity | kcal/h | 623500 | 721500 | 940000 | 1083600 | 1243600 | |

| kw | 725 | 839 | 1093 | 1260 | 1446 | ||

| Consumption | kw | 160 | 180 | 230 | 272 | 305 | |

| Operation current | A | 273 | 305 | 373 | 452 | 503 | |

| Startup current | A | 612D/943D D | 665D/1023D D | 465Y/1442D | 586Y/1853D | 650Y/2029D | |

| Capacity control | % | 100-75-50-25-0 | |||||

| Compressor | Type | - | Half-closed and double-screw type | ||||

| Quantity | - | 2 | |||||

| Startup type | - | Divided winding starting | Y-Δ | ||||

| Oil heater | W | 300x2 | |||||

| Chilled oil | Type | - | B320SH | ||||

| Filling quantity | L | 22x2 | 28x2 | ||||

| Refrigerant | Type | - | R-22 | ||||

| Filling quantity | KG | 54x2 | 61x2 | 78x2 | 92x2 | 104x2 | |

| Throttling | - | Thermostatic expansion valve | |||||

| Evaporator | Type | - | Tube-in-shell high efficient heat exchanger | ||||

| Chiller water flow | m³/h | 125 | 144 | 188 | 217 | 249 | |

| Pressure expense | KPa | 65 | 65 | 67 | 67 | 69 | |

| Water pipe joint | PT | 6" | 6" | 6" | 8" | 8" | |

| Condenser | Type | - | Tube-in-shell high efficient heat exchanger | ||||

| Chilling water flow | m³/h | 162 | 188 | 244 | 282 | 323 | |

| Pressure expense | KPa | 62 | 62 | 65 | 67 | 67 | |

| Water pipe joint | PT | 4"x2 | 4"x2 | 5"x2 | 5"x2 | 5"x2 | |

| Protection device | - | High pressure switch, low pressure switch, Anti-freezing switch, fusible plug, compressor over-heat protection, motor over-heat protection, exhaust air over-heat protection, pump over-load protection, oil over-heat protection, phase reverse protection, voltage insecure, cooling water over-heat protection, chilled water flow protection, cooling water flow shortage protection, cooling tower over current protection, and so on. | |||||

| External dimensions | L | mm | 3760 | 3760 | 4100 | 4100 | 4250 |

| W | mm | 1400 | 1400 | 1600 | 1750 | 1750 | |

| H | mm | 2040 | 2080 | 2260 | 2290 | 2360 | |

| A | mm | 1600 | 1600 | 1600 | 1600 | 1600 | |

| B | mm | 1290 | 1290 | 1480 | 1630 | 1630 | |

| C | mm | 1130 | 1135 | 1240 | 1270 | 1305 | |

| D | mm | 265 | 265 | 290 | 290 | 290 | |

| E | mm | 175 | 175 | 240 | 240 | 250 | |

| F | mm | 375 | 375 | 450 | 450 | 430 | |

| G | mm | 545 | 545 | 500 | 500 | 775 | |

| I | mm | 250 | 250 | 100 | 100 | 90 | |

| Net weight | Kg | 3750 | 3880 | 5050 | 5340 | 5600 | |

| Operating weight | Kg | 4110 | 4250 | 5490 | 5830 | 6260 | |

| Noise | dB(A) | 80 | 82 | ||||

Remark:

1) Condition for parameter test: temperature of chilled water: inlet 12°C,outlet 7°C;temperature of chilling water: Inlet 30°C, outlet 35°C.

2) Noise test: 1m away from the due front of the machine, 1.5m high away from the machine (noise: below 30dB)

3) "-D" means double compressor.

4) Any special requirements have to be advised before order.

Please excuse for not note if some specifications of products are changed.

Application:

AMC-WS Series screw type compressor water Chillers are fixed with German-made BITZER brand semi-closed screw type compressors. Aumax water chillers charged with R22 as standard refrigerants and R407C as optional refrigerants. Aumax industrial chillers equipped with high efficiency tube-in-shell type condenser and evaporator ensure stable heat exchange and convenient maintenance; advanced controller with built in microprocessor which has a powerful and excellent performance.

AMC-WS centralized Water-cooling System are main composed of compressor, condenser, evaporator and expansion valve. It is adopted single-stage vapor compression refrigeration system, by the principle of inter-conversion between gaseous and liquid refrigerator, to absorb and release heat. So that, achieving the results of refrigeration.

Features:

Semi-closed type, double screws compressors are made in Germany with high efficiency and performance.

Stopless compressor output capacity adjusting function are designed to save power.

"Watchdog" technology makes microprocessor able to automatically diagnose and solve the problems.

High efficiency evaporator and condenser built strictly according to national standard.

Function of fault query and fault statistics, easy to analysis the fault and make improvement.

Fixed with shockproof pad to reduce vibration and noise.

Special touch screen panel with multi-language, long service life more than 10 years.