- sales@aumax-plast.com

- 008613819843291

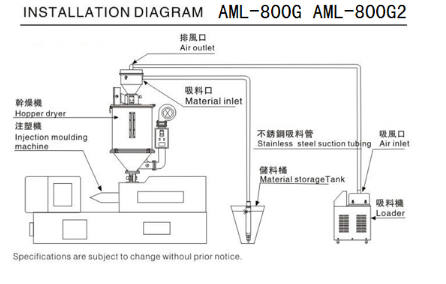

Separate Vacuum Autoloader (Single-phase)

AML-700G

Product details

Specification:

| Model | Motor | Conveying Capacity (kg/hr) | Hopper Capacity (L) | Conveying Pipe diameter (mm) | Dimensions(mm)H x W x L | Weight(KG) | ||||

| Type | Power | Main Body | Hopper | Main body | Hopper | |||||

| AML-700G | Carbon Brush | 1.5HP/1Phase | 300 | 6 | Ø38 | 550x450x300 | 450x350x250 | 20 | 5 | |

Please excuse for not note if some specifications of products are changed!

Note:

1) The test condition of conveying capacity: vertical distance 4 meters, horizontal distance 1 meter.

2) The standard power voltage for AML-700G is 1Ø 220V 50/60Hz.

Application:

AML series separate vacuum hopper loaders are suitable for conveying material over long distance. The machine adopts stainless steel hopper to ensure no contamination to raw material. The machine equipped with high efficiency and high pressure air pump, features light weight, durable and great suction power, easy installation and operation.

Features:

Microprocessor controller for ease of operation and has multiple alarm indicators.

Motor overload protector ensures long motor lifespan.

Audible material shortage alarm.

Filter designed for easy cleaning and has filter status checking window for easier monitor of filter condition.

Both vacuum hopper and photo sensor hopper can be directly mounted on molding machine's feed port.

The above mentioned loaders adopt stainless steel mesh as standard.

It is available to select 6L/12L vacuum hopper, both of which can be directly installed on injection molding machine.

Proportional valve is available as option, which is adopted to mix virgin and regrind material, as well as instantly recycle regrind material.