- sales@aumax-plast.com

- 008613819843291

Product details

Specification:

| Name | Single Dosing Unit | Double Dosing Unit | ||||||

| Model | CM30-24 | CM30-20 | CM30-16 | CM30-12 | CM30-08 | CM-D30/30 | CM-D30/50 | CM-D50/50 |

| Motor Power (W) | 30 | 30 | 30 | 30 | 30 | 30×2 | 30×2 | 30×2 |

| Motor Speed (rpm) | 3000 | 3000 | 3000 | 3000 | 3000 | 3000 | 3000 | 3000 |

| Mixing Power (W) | 90 | 90 | 90 | 90 | 90 | 90 | 90 | 90 |

| Screw Diameter (mm) | 24 | 20 | 16 | 12 | 08 | * | * | * |

| Output(kg/h) | 0.8-38 | 0.4-20 | 0.2-10.0 | 0.1-3.0 | 0.08- 1.5 | ** | ** | ** |

| Hopper (L) | 12 | 12 | 12 | 12 | 12 | 12×2 | 12×2 | 12×2 |

| Reducing Ratio | 30 | 30 | 30 | 30 | 50 | 30 / 30 | 30 / 50 | 50 / 50 |

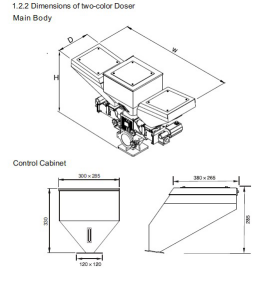

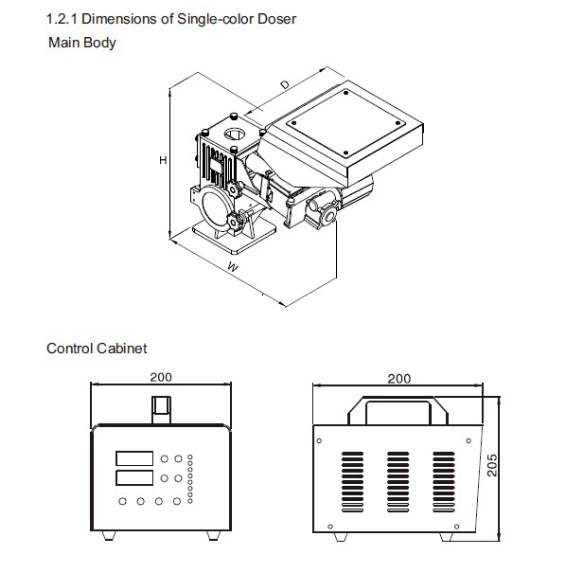

| Dimensions: | ||||||||

| H mm | 420 | 420 | 420 | 420 | 420 | 420 | 420 | 420 |

| W mm | 550 | 550 | 550 | 550 | 550 | 1045 | 1045 | 1045 |

| D mm | 295 | 295 | 295 | 295 | 295 | 295 | 295 | 295 |

| Weight (kg) | 17 | 17 | 17 | 17 | 17 | 30 | 30 | 30 |

Please excuse for not note if some specifications of products are changed.

Note:The standard power supply is 220V 50/60Hz. Other power supply is available.

Application:

CM series volumetric dosers are suitable for auto-proportional mixing of new materials, regrinds, master batch and additives. A brushless DC motor is used in this series. According to the set mixing proportion, the microprocessor accurately controls rotation of the high precise dosing screw to squeeze out materials with an accuracy of ±1%. A gear motor with deceleration ratio of 30:1 or 50:1 is coupled to a dosing screw of 1 2, 14 or 16mm diameter to give a total of six models with output ranging from 0.1 to 50 kg/hr. Double masterbatch dosers can be supplied to match with two single color dosers if required by clients.

Features:

1) Use brushless DC motor and free from maintenance.

2) Everlasting data memorizer and settings storage.

3) Microprocessor control, intelligent and accurate in calculation.

4) External signals can be directly interfaced with control box.

5) Dosing screws are chrome plated for durability.

6) Unit is comprised of standard modules for ease of cleaning, disassembly and interchangeability.

7) Three - tube hopper magnet is equipped at the base of single color doser to absorb metal impurities so to prevent screw of molding machine from damage.

8) Blender is a standard accessory for double color doser to make the material evenly mixed, while also a optional accessory for single color doser to do so.

9) Main material hopper is a standard accessory for double color doser. It is optional for single color doser.

10) When work with SHD - 100 or models above SHD - 160U, installation base should have an additional large flange mounted on ( without three – tube hopper magnet ).

11) Upon request, it can be built to comply with worldwide electrical safety standards ( For example : CE, UL, CSA, JIS etc. ).