- sales@aumax-plast.com

- 008613819843291

Soundproof Plastic Granulator

AMG-400GQ AMG-500GQ AMG-600GQ AMG-800GQ

Product details

Specification:

| Name | Soundproof Plastic Granulator / Plastic Crusher | |||||||

| Model | AMG-400GQ | AMG-500GQ | AMG-600GQ | AMG-800GQ | ||||

| Power | kw | 11 | 15 | 18.5 | 30 | |||

| Rotor Speed | rpm | 560 | 560 | 560 | 560 | |||

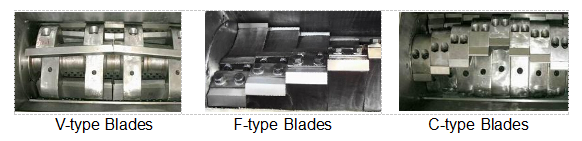

| Rotating Blades | V type | pcs | 6 | 6 | 6 | 6 | ||

| F type | 12 | 15 | 18 | 24 | ||||

| C type | 24 | 30 | 36 | 48 | ||||

| Fixed Blades | pcs | 2 | 2 | 4 | 4 | |||

| Screen Diameter | Ø10 | Ø10 | Ø12 | Ø12 | ||||

| Chamber Size | mm | 320x400 | 320x500 | 460x600 | 460x800 | |||

| Output | kg/h | 300~550 | 400~650 | 500~700 | 600~900 | |||

| Noise | dB(A) | 70~80 | 70~80 | 70~80 | 70~80 | |||

| Magnet at Feeding Mouth | O | O | O | O | ||||

| Blower Conveying & Cyclone System | √ | √ | √ | √ | ||||

| Weight | kg | 650 | 750 | 1500 | 1800 | |||

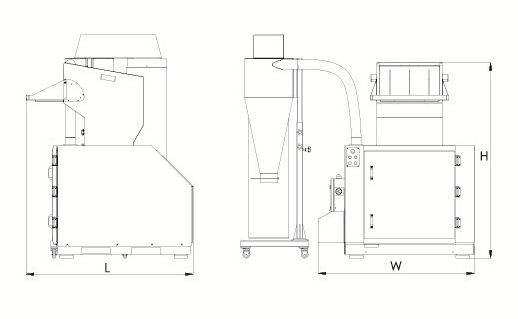

| Dimensions: | ||||||||

| L | mm | 1290 | 1290 | 1275 | 1275 | |||

| W | mm | 1375 | 1475 | 1620 | 1820 | |||

| H | mm | 1630 | 1630 | 2020 | 2020 | |||

Please excuse for not note if some specifications of products are changed.

Note:

1)"√"is standard configuration," O " is optional to purchase.

2) V-type rotating blades are standard type for AMG-600GQ/800GQ;

F-type flat rotating blades are standard type for AMG-400GQ and AMG-500GQ;

C-type claw rotating blades is optional to purchase.

3)The maximum crushing output depends on the screen diameter, material quality and feeding frequency.

4) The screen mesh diameter can be made according to customers’ request.

5)The running noise depends on varied shredding material.

6)The standard power supply is 3Ø 380V 50Hz. Other power supply is available.

Application:

AMG-GQ Series Quite Soundproof Central Plastic Granulators are used to granulate various kinds of plastic wastes. This series plastic crushers and grinders are suitable to crush different hard and soft plastic wastes in different shapes like PET Bottles, PP/PE films, PVC pipes and fittings, plastic blocks, plastic sheets, etc. The machine equipped with high efficiency conveying blower and cyclone system. Totally enclosed design insures a low running noise.

Features:

SKD11 material blades and special designed blades structure insure high efficiency and performanceOptimized designed bearings block keep dust away, with low running temperature for long life using.

V-shaped blades, Claw blades and Flat blades are optional for different plastic wastes.

Electric motor screw device for opening and closing cutting chamber to save manpower.

Separate structure design for cutting chamber and screen mesh, easy to clean and maintenance.

Safety switch to protect people, overload device to protect motor.

Optional dust-separator is available.

Fixed with shockproof pad to reduce vibration and noise.